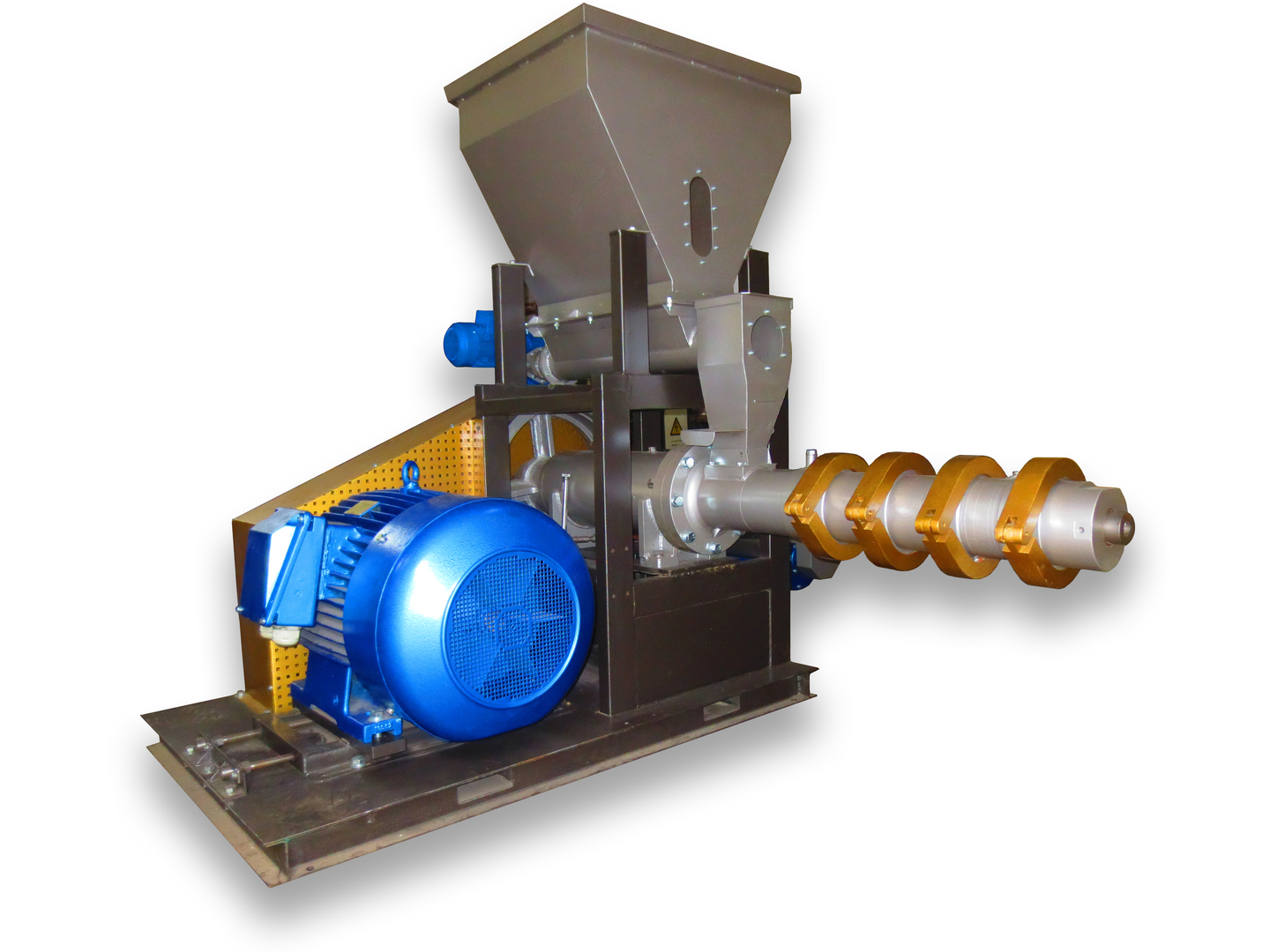

Grain extruder with a high-frequency vibrating device and a magnetic trap model GE - 1.0 “DANKER” TM

| Productivity | 1000 kilograms per hour |

|---|---|

| Operating temperature range | + 105°C - +140°C |

| Weight | 1500 - 1800 kilograms |

| Power consumption | 90 kW |

| Dimensions (length/width) | 2300 mm./2200 mm |

| Price | 23 000 EURO |

Description>

Grain extruder with a high-frequency vibrating device and a magnetic trap model GE - 1.0 “DANKER” TM. It is designed to produce full-fat extruded soybeans in the production of feed by extrusion, which allows to improve the quality of feed several times. The main auger shaft of high hardness and wear resistance consists of separate sections, which allows replacing only the worn section. The modified working chamber and additional sections of the main auger shaft make it possible to customize the equipment for any type of raw material. A high-frequency vibration device prevents the raw material from sticking in the sections of the main screw shaft turns and promotes the advancement of the raw material in the middle of the working chamber, which facilitates the operation of the press and increases its productivity. The extruder's electronic control panel is equipped with a “foolproof” system, a speed converter for the main screw shaft and feeder, and a high-frequency vibration control system, which makes it possible to select the optimal press operation mode depending on the raw material. When developing and manufacturing equipment, we take into account the wishes and specifications of the customer. Spare parts are always in stock. Maximum equipment. Minimum commissioning and adjustment work. Work in an autonomous, non-stop mode. One person to operate the machine. - improved technical characteristics - manufacturing of extruders in accordance with the customer's specifications - all working parts are highly hardened and consist of sections, which allows replacing only worn out section - electronic control panel for operation, temperature and humidification control raw materials, with a “foolproof” system. - service personnel 1 employee - maximum equipment and readiness for work - minimum commissioning and adjustment work - robust design and long service life - structural steel with high-strength anti-corrosion paint and varnish coating

Leave a request and we will respond as soon as possible

We undertake projects of any complexity.

Contact us and get a detailed consultation from a specialist today