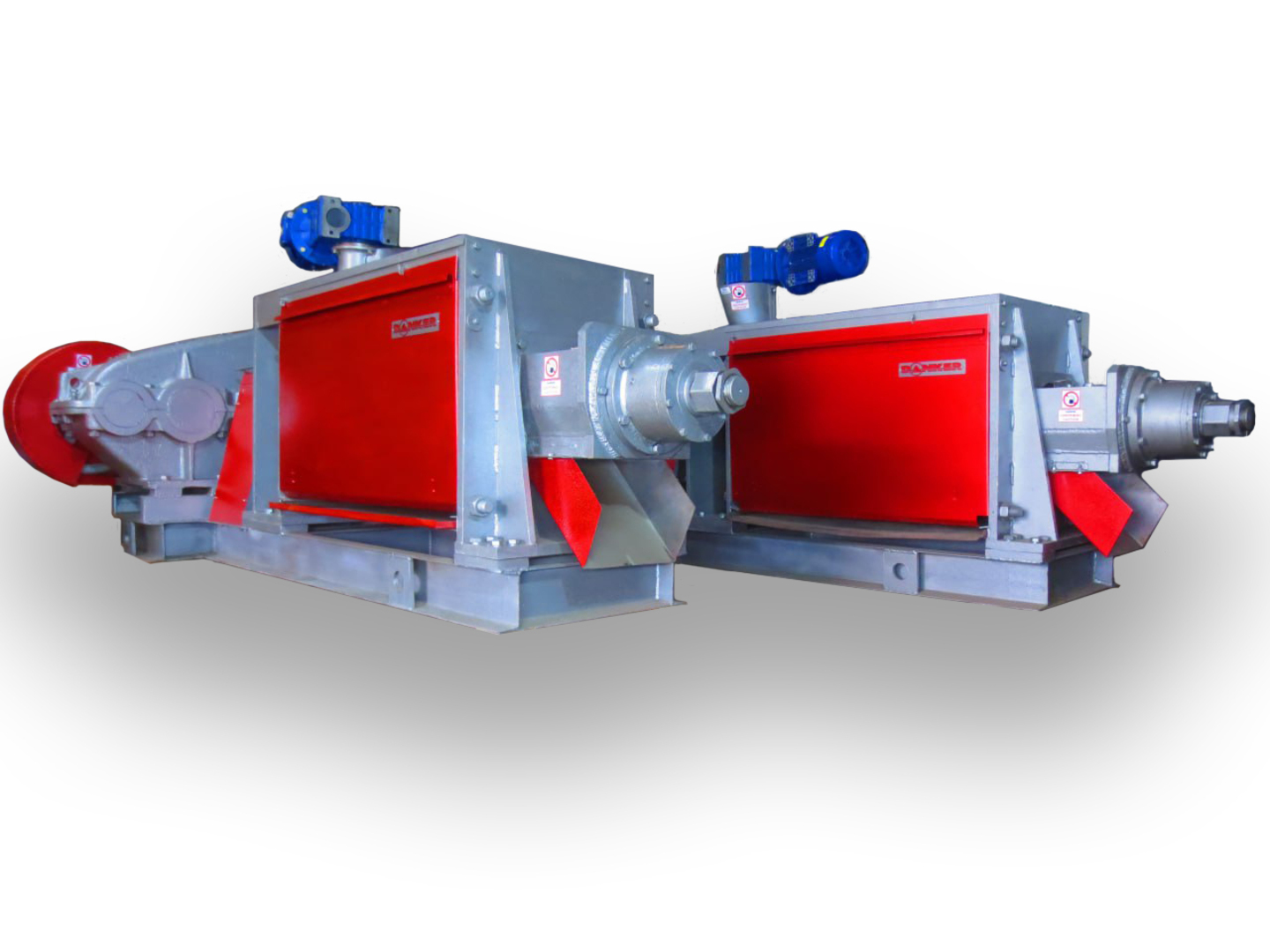

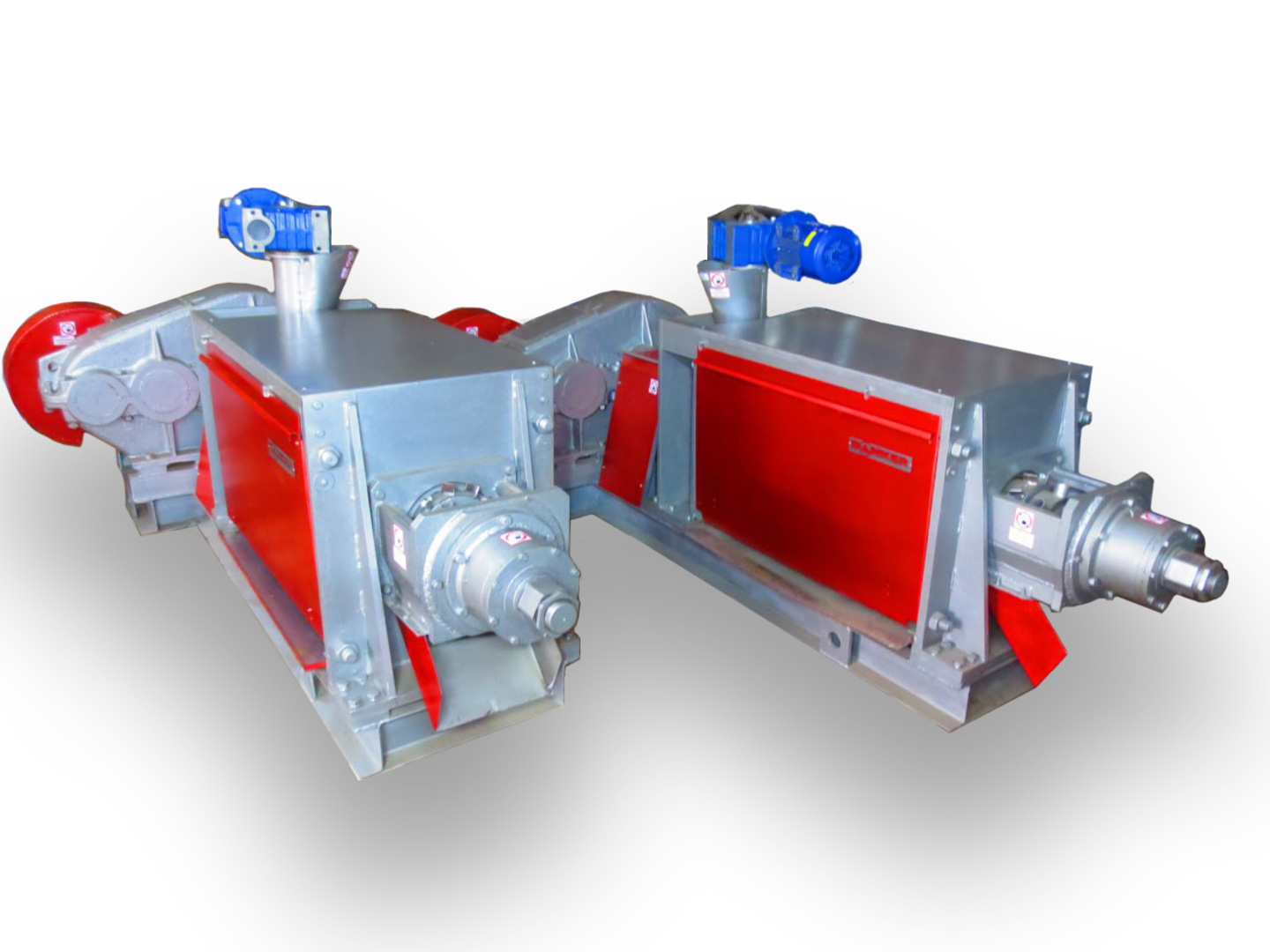

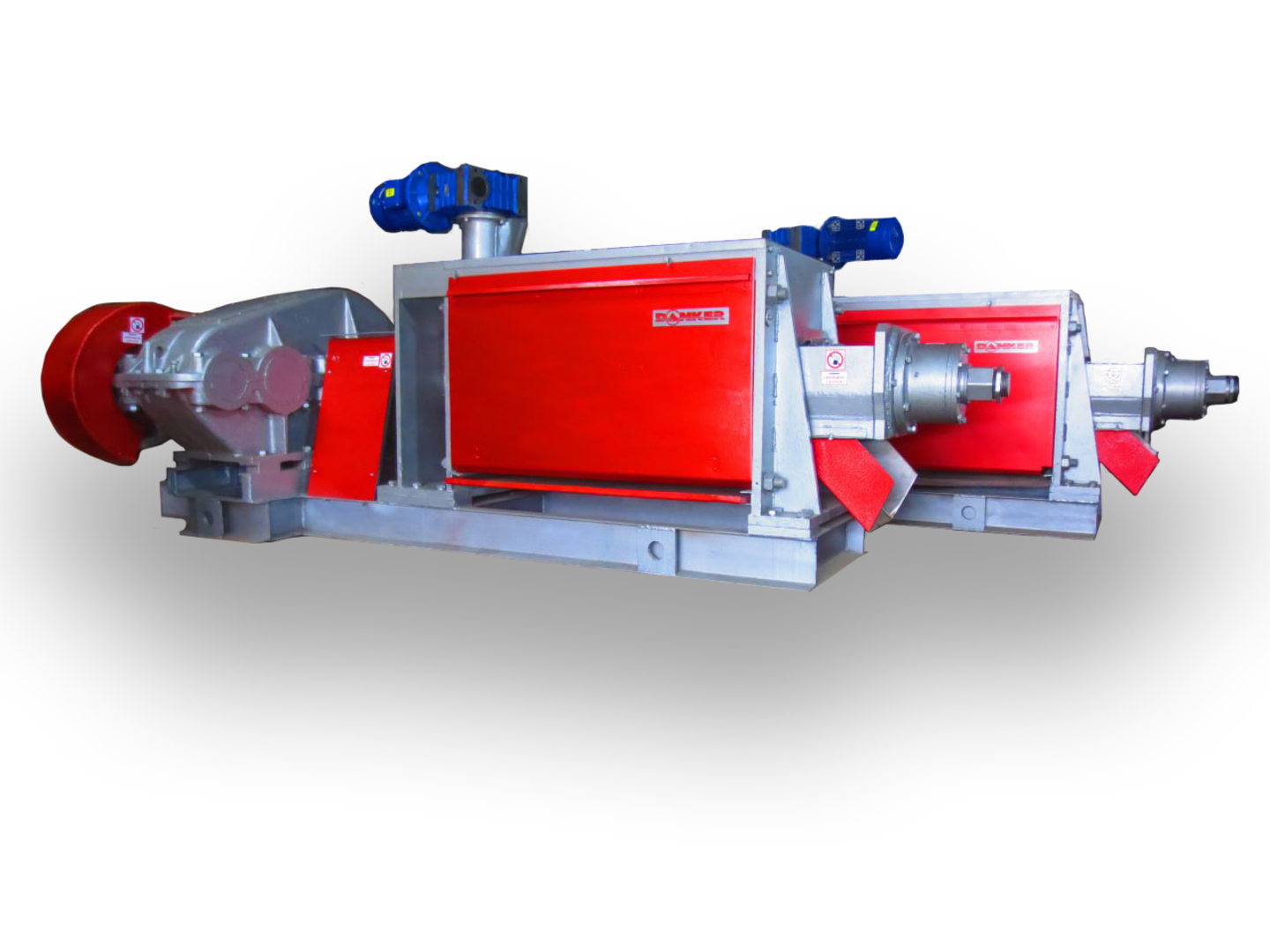

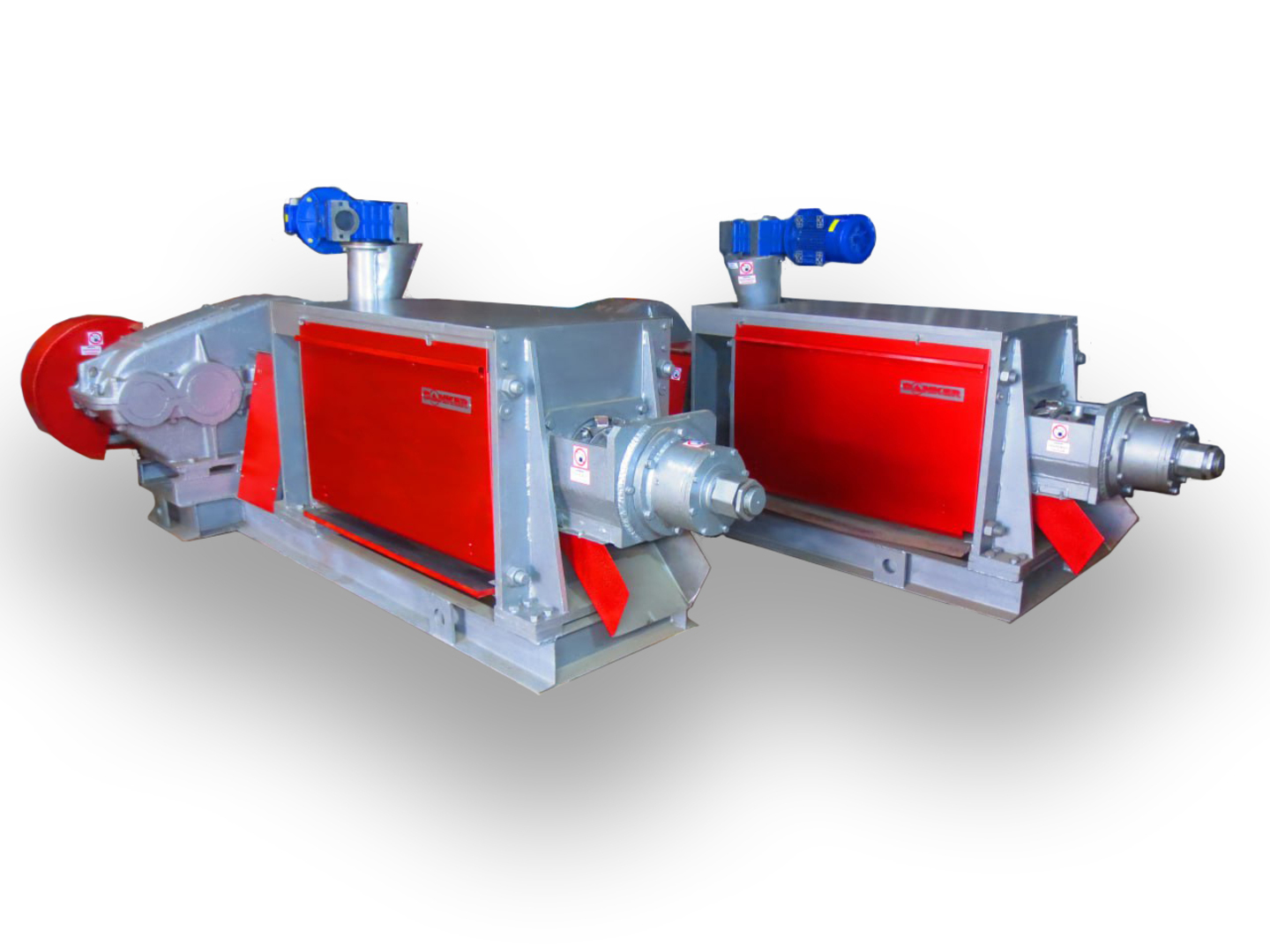

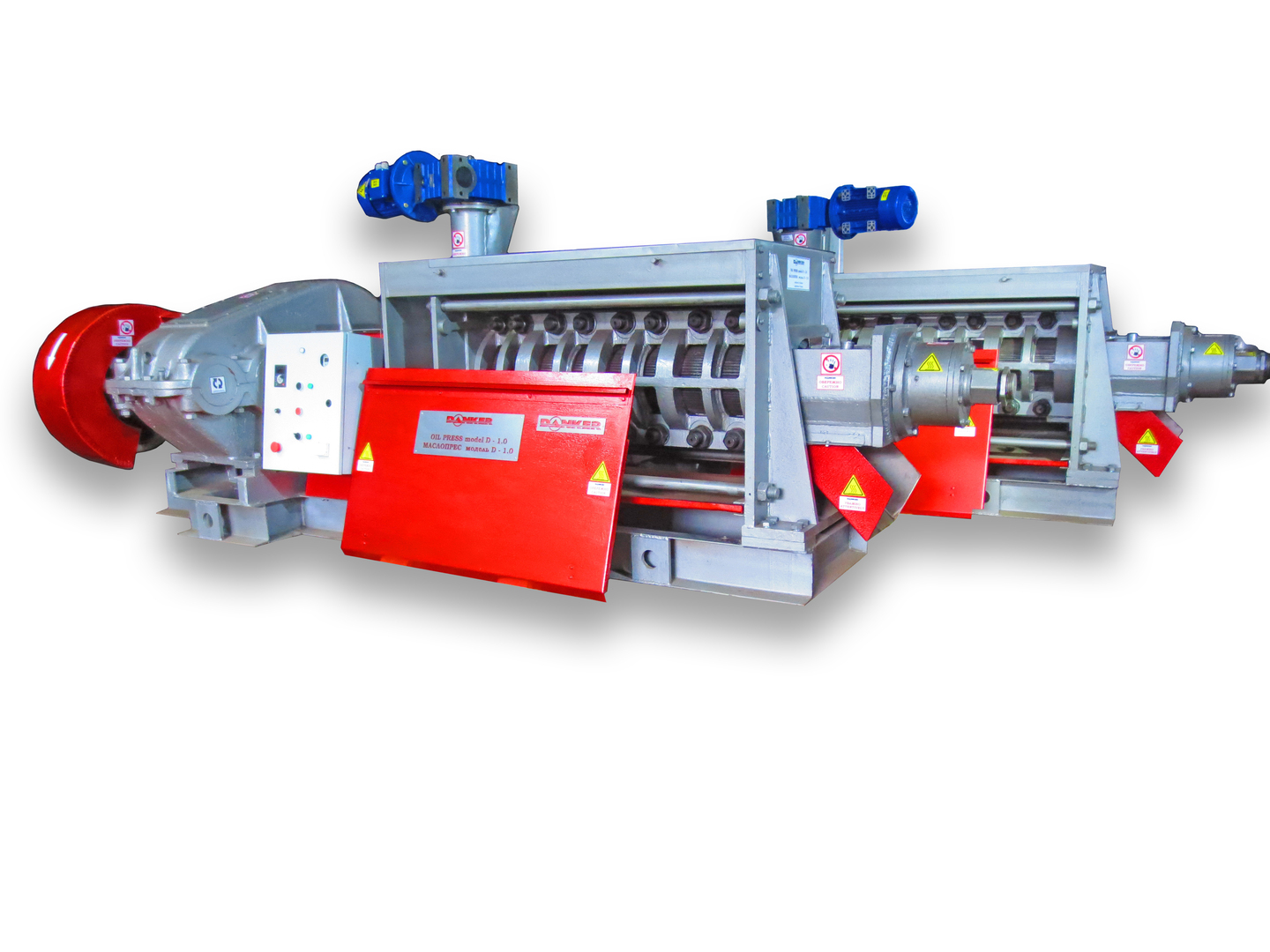

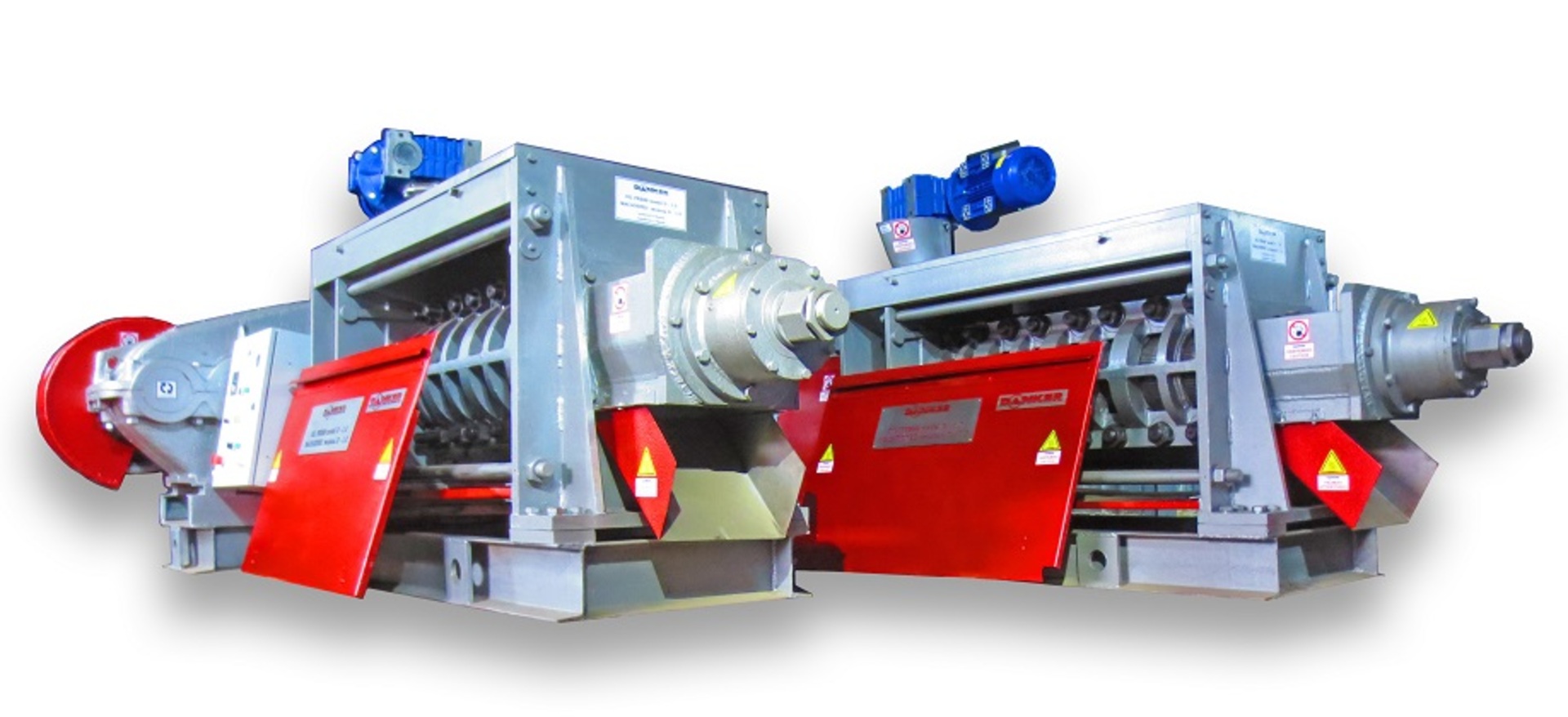

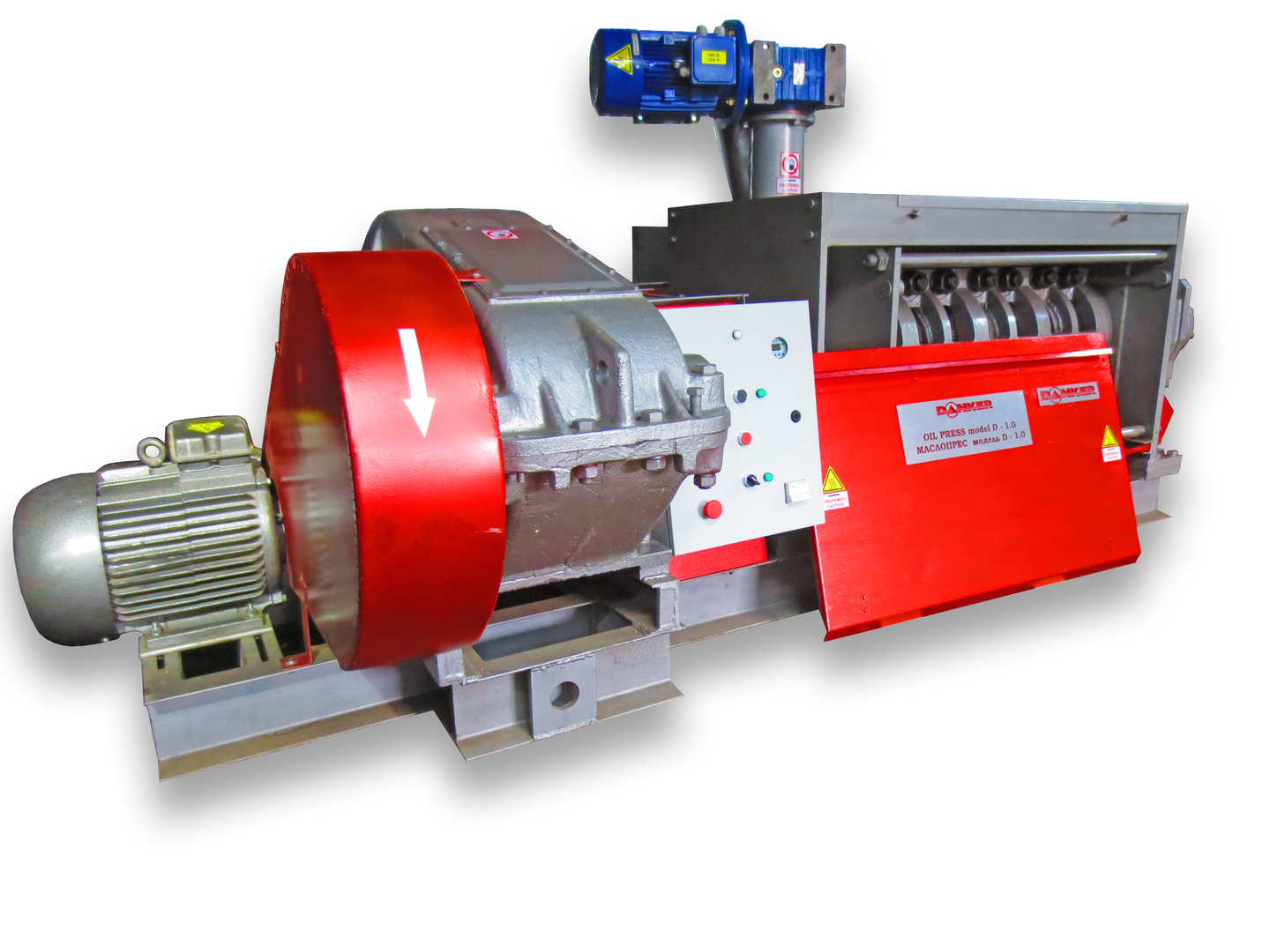

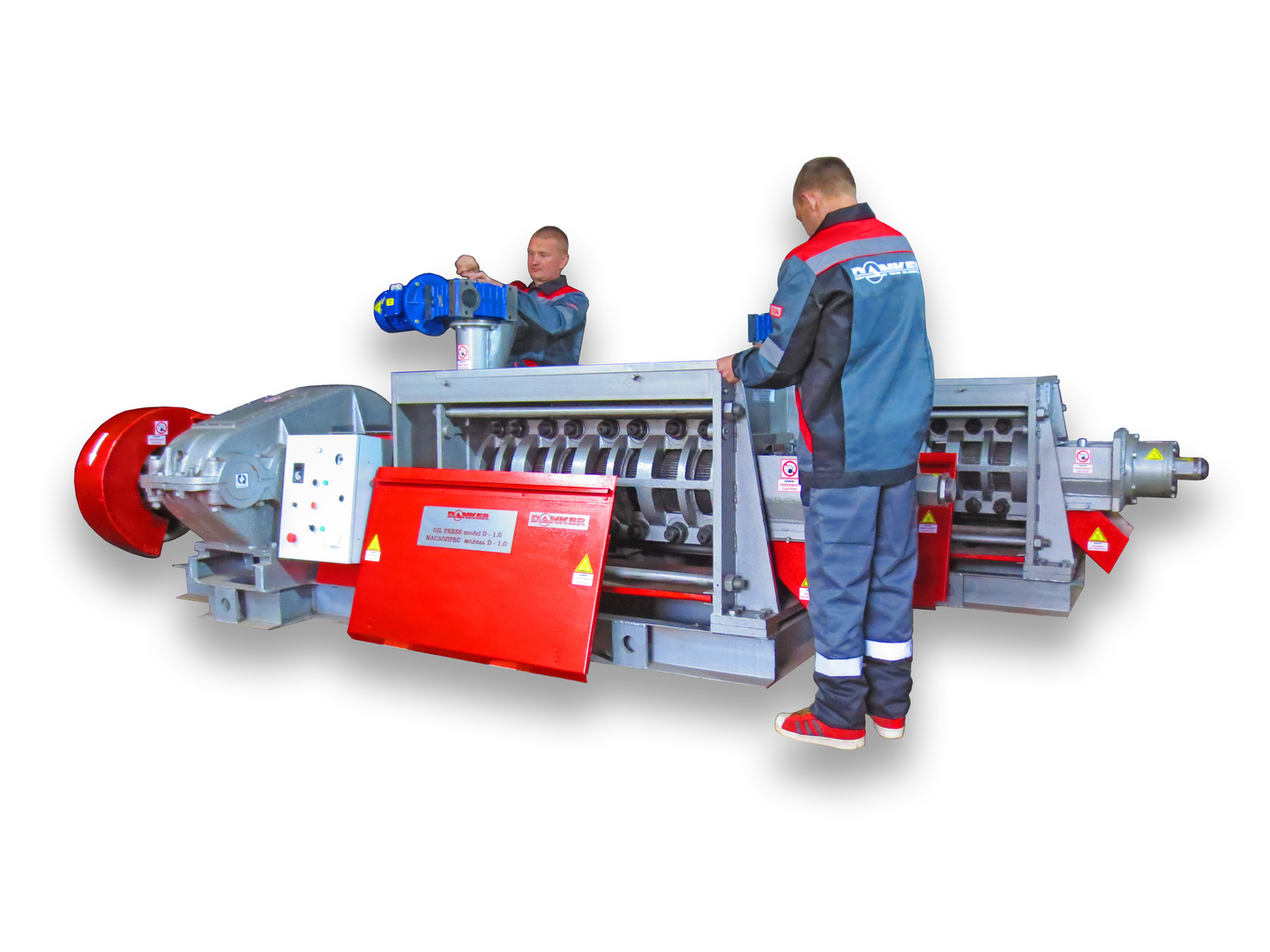

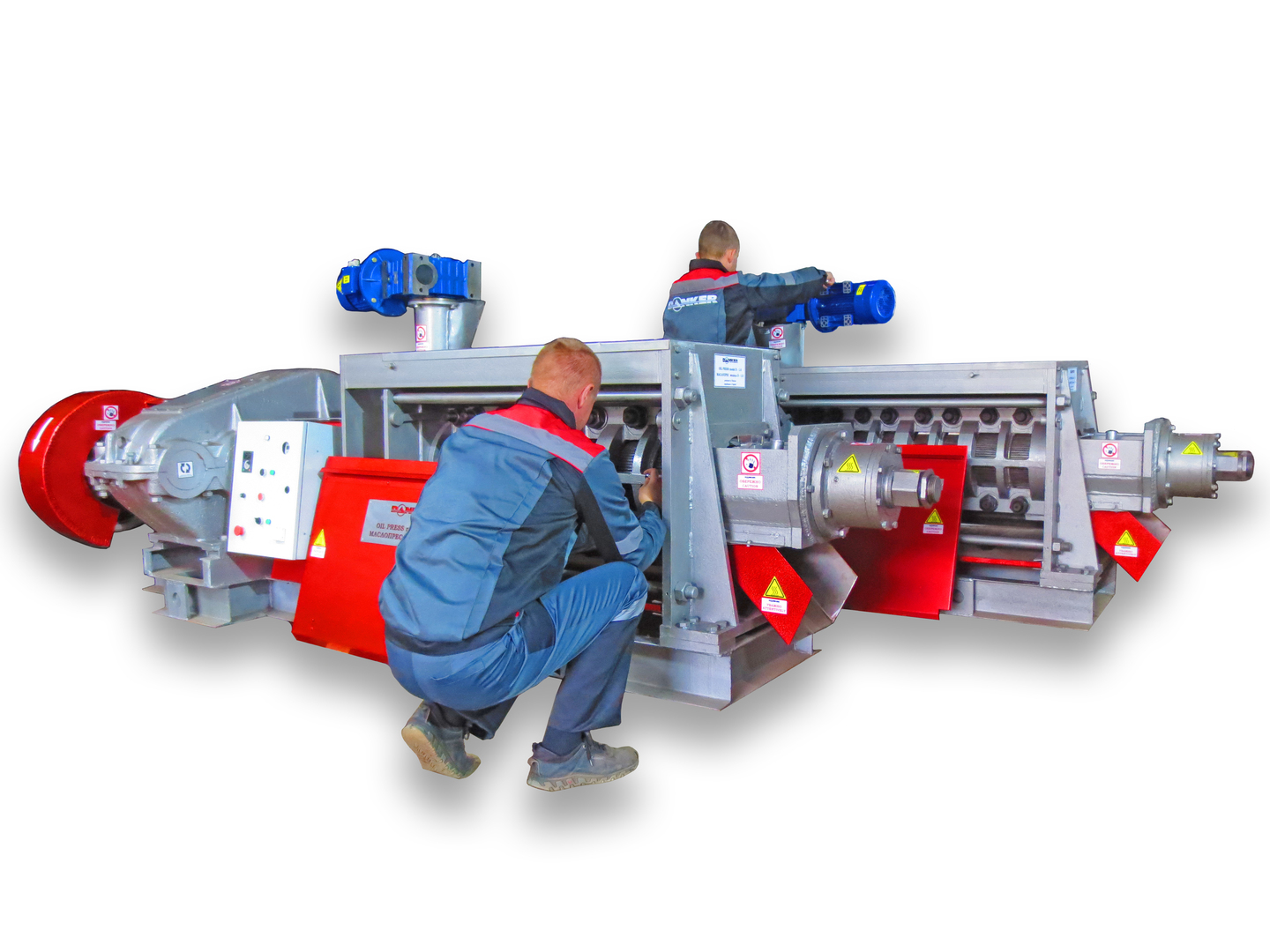

Universal oil press with a modified mill chamber and ultrasonic emitters model POD - 1.0 “DANKER” TM

| Productivity | 1000 kilograms per hour |

|---|---|

| Adjustable main shaft speed | 56 - 92 revolutions per minute |

| Oil content of cake (oilcake) | min: 9%, max: 11% |

| Weight | 2800 kilograms |

| Power consumption | 22 kW |

| Dimensions (length/width) | 3900 mm./1500 mm |

| Price | 31 800 EURO |

Description>

The screw oil press is designed for pressing various oilseeds in the production of high-quality vegetable oils. The “cold” pressing technology allows preserving useful nutritional, healing and medicinal properties of vegetable oils. Adjusting the speed of the main screw shaft allows you to set up the press for “cold” or “hot” pressing of raw materials. The main auger shaft of high hardness and wear resistance consists of separate sections, which allows replacing only the worn section. The modified sieve chamber prevents idle rotation of the raw material, increasing the friction force and efficiency of squeezing the raw material, which increases productivity and reduces the oil content of the cake. Additional clamping plates of the cake chamber make it possible to adjust the press to any type of raw material. Ultrasonic emitters prevent the raw material from sticking in the sections of the main screw shaft turns and promote the movement of the raw material in the cake chamber, which facilitates the operation of the press and increases its productivity. The electronic control panel of the press operation process is equipped with a “foolproof” system, a speed converter for the main screw shaft and feeder, as well as a control system for ultrasonic emitters, which generally makes it possible to select the optimal press operation mode depending on the raw material. When designing and manufacturing presses, we take into account the wishes and specifications of the customer. Spare parts are always in stock. Maximum equipment. Minimum commissioning and adjustment work. Operation in autonomous, non-stop mode. One person to operate the machine

Leave a request and we will respond as soon as possible

We undertake projects of any complexity.

Contact us and get a detailed consultation from a specialist today